Not known Facts About Sheroz Earthworks

Not known Facts About Sheroz Earthworks

Blog Article

Rumored Buzz on Sheroz Earthworks

Table of ContentsThe Single Strategy To Use For Sheroz EarthworksThings about Sheroz EarthworksSheroz Earthworks for BeginnersTop Guidelines Of Sheroz EarthworksGetting My Sheroz Earthworks To Work

For any earthwork service provider, it is vital to do collaborate with quality, accuracy, and on time. Using maker control in job equipments allows maximizing the different phases in the earthwork process, from planning to the maintenance phase - fj dynamics autosteer review. The machine control system assists the maker driver in obtaining the target aircraft promptly and conveniently

The maker control system overviews the driver with centimeter accuracy. With Xsite PRO 3D, you'll always understand precisely exactly how much to cut or fill up. Your local Xsite technical support can direct you and help with any issues without seeing the website. Remote assistance conserves money and time, as it lessens downtime in jobsites.

Indicators on Sheroz Earthworks You Need To Know

Our system's parts are meticulously designed to hold up against the harsh problems of building and construction websites. Comparison of the same job carried out utilizing maker control versus the traditional technique exposes that, on average, the traditional technique needs 50% even more time to achieve the exact same task as the technology-assisted technique.

Sounds great? Go into the Xsite maker control system; it's right here to offer you with a considerable benefit when functioning with earthmoving equipment. Discover exactly how Xsite Machine Control can enhance your efficiency and make sure job security! We understand that discovering a new modern technology could seem like a drag, but don't stress! Our friendly and specialist local assistance solutions have obtained you covered, guaranteeing that you can keep working smarter without disturbances while on duty! Through remote support, your local Xsite dealership can provide assistance or troubleshooting without having to see the site! What sort of excavators does machine control fit? Xsite Equipment Control systems can be installed to any kind of excavator from mini excavators to huge mining excavators.

Just how does device control job? In 2D systems, the equipment is furnished with adjusted inclination sensing units. These sensing units are installed on the pre-determined components of the device in excavators the sensor are normally placed to the frame, boom (or booms), miner arm and to the quick coupler - trimble gps. By making use of the data gotten from these sensors the system can determine the precise placement of the excavators bucket pointer in significance to a recommendation factor.

The system is very easy to discover the fundamentals can be instructed in under one hour of training. How does the remote support work? A cordless net connection makes it possible to establish a remote connection between the device control system and the service.

9 Easy Facts About Sheroz Earthworks Described

Xsite Maker Control systems sustain open common file formats, allowing seamless details circulation from one system to one more. Depending on your choice of system (with or without placing, i.e., 2D or 3D), your machine is furnished with inclination sensing units, a controller system, and a display/operating panel.

Several hardware and software services exist to help establish an equipment's present position on the earth and compare it with a preferred design surfaceand building operators can do even more to utilize the advantages. Maker control is using different placing sensing units and a display to offer the driver with a referral in between the setting of the pail or blade and the target quality.

Depending on the configuration, machine control systems can give the driver with an easy aesthetic overview to container or blade position, or can instantly move the blade to quality by talking with the equipment's hydraulics - http://prsync.com/sheroz-earthworks/. There are maker control systems available for almost any type of device: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, grating machines, and pavers

The Facts About Sheroz Earthworks Uncovered

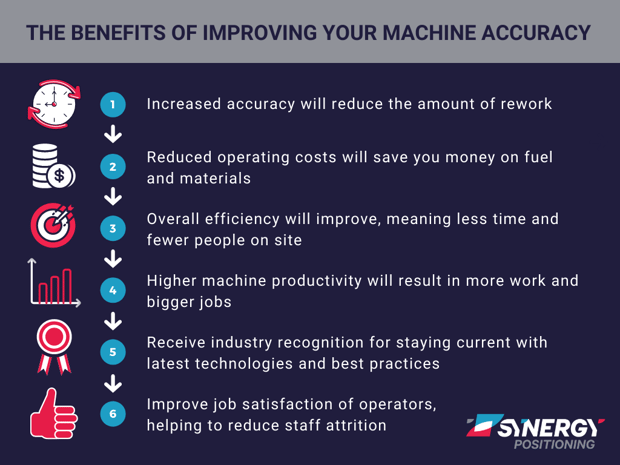

Machine control can also aid raise performance and reduce general expenses. Building and construction tools without device control will certainly come to be a Learn More point of the past and the benefits gained from it will be many.

Trimble equipment control systems provide a myriad of advantages to anybody who utilizes earthwork machinery and, at EarthCalc, we can supply you with 3D declare your equipment control-enable devices. Not sure if equipment control deserves the price? Consider the following reasons you need to consider this alternative.

Making use of GPS straightened with your 3D layout documents, these systems essentially assure that you will certainly get rid of or put the proper amount of material at the construction site. On a lot of building and construction sites, remodel is a common and frustrating reality, but with Trimble device control, you can get rid of the need for rework.

The Sheroz Earthworks Ideas

Often, with Trimble device control, you can get rid of excess devices at a particular work website. For instance, a task that might have called for using three or four items of excavating tools currently might need only two tools to achieve the exact same job in much less time. This permits you to move your tools to one more job site and manage numerous work at one time.

Report this page